Blow Molding

Our blow molding machines cover a range from 1 to 150 litres that lets us to manufacture a big variety of products. Explore simplicity and quality with us.

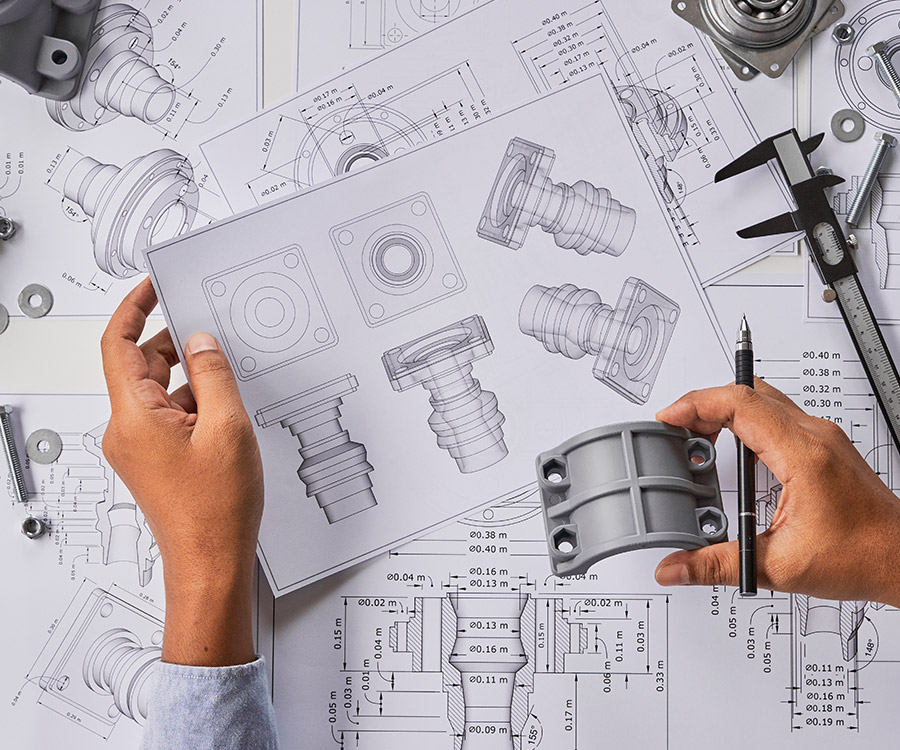

We specialize in blow molding, a sophisticated technique for crafting high-quality hollow plastic products. Our commitment to quality sets us apart.

Why Choose Yıldırım Plastik for Blow Molding?

- Creative Design: Our team excels in designing functional blow-molded products.

- Team Experience: Our skilled team ensures expertise in handling complex geometries and achieving superior finishes.

- Material Expertise: Choose from a variety of materials guided by our team for your project.

- Custom Mold Craftsmanship: Skilled craftsmen create molds for high-quality and efficient production.

The Blow Molding Process

- Material Selection: Collaborate to choose the ideal material based on specific requirements.

- Design and Mold Fabrication: Our team tailors molds to your specifications for creative and functional designs.

- Blow Molding Process: Plastic parison is heated, placed in the mold, and inflated, taking the precise shape.

- Cooling and Setting: The blown part cools and sets in the mold, locking in the desired form and characteristics.

- Quality Control: Each part undergoes thorough inspection for specifications and quality standards.

Applications of Blow Molding

Used in various industries for lightweight, durable, and customizable products, from beverage and packaging to automotive and industrial.

Contact us to explore the potential of high quality in blow-molded products.